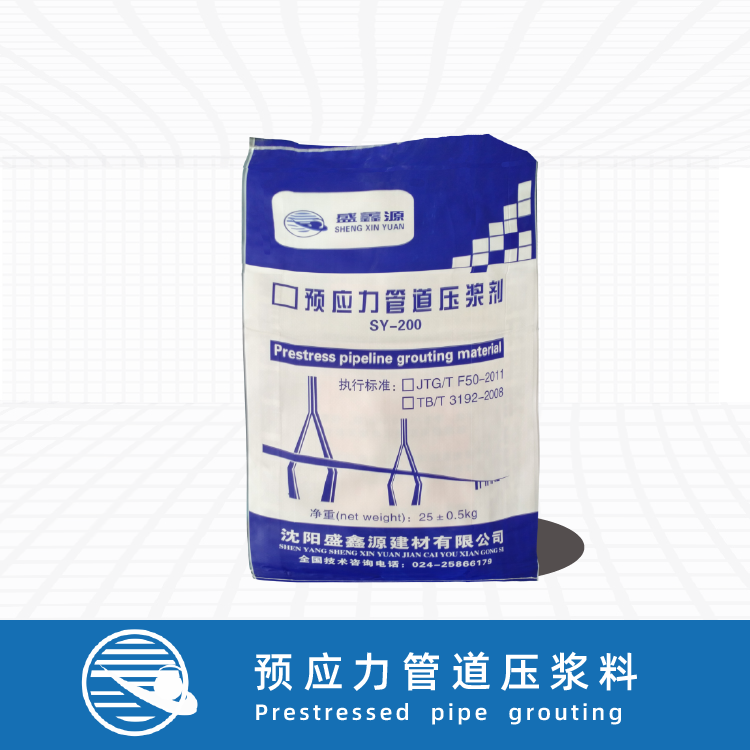

SY-Grouting material

As a privately-owned enterprise, Sheng Xinyuan Building Materials is like a grain of sand in the vast ocean of the market economy. It has tenaciously rooted itself in the field of building admixtures, attracting talent from all walks of life: specializing in technology research and development and services, focusing on creating better and more applicable products, and acting as a unique "one-stop concrete solution" provider in the building admixture industry. "Being an expert in the admixture industry and a consultant in the concrete industry" is the code of conduct for Sheng Xinyuan people. Ten years of honing a sword. Now, the sharp edge appears.

Keyword:

Sheng Xinyuan Building Materials丨Water Reducer Series丨Crack Resistance and Waterproof Series丨Early Strength and Antifreeze Series丨Functional Series

Category:

Product Description

Product Introduction Please first confirm that the product you are viewing is the product you need and meets your procurement standards You can click on the Online Consultation button on the page, and the customer service will help you find the required product based on your description.

Construction Methods Please read the construction methods carefully and pay attention to the construction points 。

After-sales Service Complete after-sales service support. If you have any questions about usage, you can call 024-89372166

Engineering Cases The choice of many customers is because we insist on product " zero defect " factory.

All products purchased by customers are delivered directly to the project site. 。

● After-sales Service

For products purchased by customers, our company will assign a dedicated person to provide full-process tracking services. The company's technical engineers will answer customers' questions in real time, and for key customers, our company will send technical engineers to provide on-site technical guidance.

Related Products

Strict quality control, creating reliable products for you

Online Comments

We will contact you within three working days. Please pay attention to your email.

Address: Shalings Industrial Park, Zhangling Road, Yuhong District, Shenyang City

Landline: 024-89372166

Email: SXYJC168@163.COM